DENIM 2025 - Design and Engineering of Neutron Instruments Meeting

DENIMXIV

We are pleased to announce the 14th edition of the Design and Engineering of Neutron Instruments Meeting (DENIM XIV), which will take place from the 21st to the 24th of October 2025, in Grenoble, France.

This meeting, organized under the International Society of Neutron Instrumentation Engineers (ISNIE), brings together engineers and experts from more than 23 national laboratories, universities, and other neutron research institutes across the world.

Sponsor companies are welcome to participate to the meeting to advertise their collaboration with engineers and scientist and bring their contribution to the discussions.

ISNIE Summer School

Just before the DENIM meeting, the ISNIE Summer School will take place, adressed to young engineers working in the neutrons science domain. The aim of the school is to present the basics engineering facts about one topic.

ISNIE engineering summer schools are one day programmes of lectures and workshops aimed at providing the basics of engineering and operation of one of neutron instruments core technologies. Introductory courses are targeted at the younger and or less experienced members of the community with the intention of being as informative as it is interactive.

Each course is prepared and delivered by a team of experts in the field selected from multiple facilities. Over the course of the day subsequent modules present a coherent overview from requirements, through engineering, to installation and operation using “best practices” to illustrate both theory and practice.

About DENIM

The International Society of Neutron Instrument Engineers (ISNIE) was established in September of 2017. The idea for the ISNIE emerged because of the very successful conferences, held annually, called the Design and Engineering of Neutron Instrument Meeting (DENIM), first held in 2012. During DENIM each year, the community reaps the benefits of building relationships and sharing expertise amongst the relatively small group of professionals who represent about twenty neutron facilities worldwide. So rather than limit this interaction to once a year, the International DENIM committee (IDC) concluded that all the benefits of DENIM and more can be achieved year-round through an International Society and hence the ISNIE has been born.

THANK YOU TO OUR GOLD AND SILVER SPONSORS !

|  |  |

| ||

|  |  |

|  |  |

-

-

09:00

→

09:10

Welcome@ISNIE School 10mSpeaker: Dr Bruno Guerard (ILL)

-

09:10

→

09:40

Overview 30mSpeaker: Karl Zeitelhack (Technische Universität München, Forschungs-Neutronenquelle FRM II)

-

09:40

→

10:25

Detector technologies I: ScintillatorsConveners: Dr Jeff Sykora (ISIS), Ralf Engels (JCNS-2)

-

10:25

→

10:40

Coffee 15m

-

10:40

→

11:25

Detector technologies II: 3He gas detectorsConvener: Julien Marchal

-

11:25

→

12:10

Detector technologies III: Boron convertorsConvener: Dr Anton Khaplanov

-

12:10

→

13:05

Lunch 55m ILL50/1er-101 - ILL 50-101 (ILL50)

ILL50/1er-101 - ILL 50-101

ILL50

30 -

13:05

→

14:05

Instrument integration: Lab and beam line visit

GROUP A: Detector Lab

GROUP B: Tech beam line -

14:05

→

14:20

Transfer 15m

-

14:20

→

15:20

Lab and beam line visit

GROUP B: Detector Lab

BROUP A: Tech beam line -

15:20

→

15:35

Coffee 15m

-

15:35

→

16:05

Instrument integration

GROUP A: Detector Lab

GROUP B: Tech beam lineConvener: Antoine LEPINE (European Spallation Source ERIC) -

16:05

→

16:20

Detectors operations 15mSpeaker: Mr Iain Sutton (ESS)

-

16:20

→

16:50

Wrap up 30mSpeaker: Karl Zeitelhack (Technische Universität München, Forschungs-Neutronenquelle FRM II)

-

16:50

→

16:55

Closure 5mSpeaker: Mr Iain Sutton (ESS)

-

09:00

→

09:10

-

-

08:00

→

09:00

Registration: Registration and coffee

-

09:00

→

09:10

Welcome @ DENIMXIV: Welcome @DENIM XIVConvener: Giuliana Manzin (ILL)

-

09:00

Welcome 10mSpeaker: Giuliana Manzin (ILL)

-

09:00

-

09:10

→

09:35

The Institute Laue Langevin Neutron Technologies 25mSpeaker: Andreas Meyer (ILL, Institut Laue Langevin)

-

09:35

→

10:15

ENDURANCE: A Modernised Suite of Instruments and Guides 40mSpeaker: Charles Dewhurst (ILL)

-

10:15

→

10:45

Coffee 30m

-

10:45

→

12:30

FACILITIES UPDATESConvener: Charles Dewhurst (ILL)

-

10:45

Australian Centre for Neutron Scattering 2024 Long Shutdown Activities 20m

ANSTO completed a six-month shutdown in 2024 to replace the cold neutron source (CNS) within the OPAL reactor pool. During this time and over the preceding year, ACNS also undertook a number of key improvements to the suite of neutron beam instruments.

The new CNS MkII in-pile assembly has a 70mm taller moderator chamber as well as several other design changes to accommodate the additional heat load and the connections to reactor pipework. A key metric of the success of the replacement was in the characterisation of the new CNS, through measurements of the neutron flux and spectrum via a combination of new and existing instrumentation. This included the temporary installation of a time-of-flight spectrometer close to the reactor face. The results demonstrated an actual gain of 5-10% more flux at wavelengths greater than 5 angstroms, which is consistent with the theoretical predictions.

Also presented are a combination of repairs and upgrades to our neutron beam instruments, including installation of new guides and monochromators. These were complemented by control systems upgrades of the safety interlocks, choppers and velocity selectors, as well as refurbishments to detectors and data acquisition electronics. Throughout the planned program of works, several technical and safety challenges were encountered. Navigating these challenges required the need to address competing priorities and constraints, with some key lessons learnt.

Speaker: Stan Lee (ANSTO) -

11:05

ILL - Recent facilty upgrades 20mSpeaker: Giuliana Manzin (ILL)

-

11:25

European Spallation Source Technical Update 20m

The European Spallation Source is preparing for initial Beam on Target, with the current planning indicating Q1 of 2026. This talk will present the technical status of the accelerator, target, controls, instruments and some of the remaining technical challenges. It will also discuss the organizational readiness as the organization prepares to shift from delivering a project into a functional facility.

Speaker: Robert Connatser (European Spallation Source ERIC) -

11:45

SINQ++: Upgrading the Swiss Spallation Source for Advanced Neutron Science 20m

The SINQ++ project is a strategic upgrade of the Swiss Spallation Neutron Source (SINQ) at the Paul Scherrer Institute (PSI), designed to address critical challenges in neutron science. Building on SINQ’s established role as a high-performing continuous neutron source, SINQ++ will introduce a new cold neutron source, doubling brightness across all instruments and offering enhancements up to 200-fold for specific applications. The upgrade aims to expand the scope of experimental possibilities at SINQ, enabling complex neutron scattering and imaging studies that demand high sensitivity and advanced instrumentation.

The project includes an extension of SINQ’s target hall to the North, creating capacity for up to six new instruments. These instruments could cater to emerging fields such as grazing incidence small-angle scattering (GISANS), advanced neutron microscopy, and backscattering for soft and biological materials. We also envisage the development of new critical infrastructure for enabling applications beyond fundamental research, including, for example, neutron irradiation for testing advanced nuclear materials, advanced radiochemistry technologies, and simulating cosmic neutron radiation for aerospace electronics certification.

In this talk, we will discuss technical aspects of the SINQ++ cold source upgrade, its integration with the existing HIPA accelerator, and innovations in instrument design, such as neutron focusing optics and 3D-printed shielding. By leveraging these advancements, SINQ++ will solidify Switzerland’s position as a leader in neutron science, addressing global challenges and fostering cross-disciplinary innovation in the European neutron ecosystem.

Speaker: Jonathan White (Paul Scherrer Institute) -

12:05

Environmental Sustainability Landscape at ISIS and Implications on Engineering and Instrument Design 20m

In the last 2-3 years the Environmental Sustainability policy, targets and governance that ISIS works within have started to change. Our Environmental Sustainability policy is increasingly focused on meeting the demands of the climate crises, and as such has taken on a new intensity and flavour. This talk will outline these policy changes, further changes that are expected, and discuss the implications on engineering and instrument design at ISIS

Speaker: William Halcrow (STFC - ISIS)

-

10:45

-

12:30

→

14:00

Lunch 1h 30m

-

14:00

→

15:30

NEW INSTRUMENTSConvener: Fréderic Thomas (ILL)

-

14:00

Early stage instrument development for WISH II and MUSHROOM at ISIS 15m

Exploring the technical and project management challenges encountered during the initial phases of developing the WISH II and MUSHROOM instruments at ISIS, with a focus on design constraints, resource coordination, and evolving scientific requirements.

Speaker: Jim Baird (ISIS - STFC) -

14:15

Construction and applications of the VSANS instrument at CSNS 15m

A multi-slit very small angle neutron scattering (MS-VSANS) instrument has been developed at the China Spallation Neutron Source (CSNS), marking the first VSANS instrument based on a spallation neutron source. This MS-VSANS instrument boasts an excellent signal-to-noise ratio and offers a broad scattering vector range from 0.00028 to 1.7 Å⁻¹. It is designed for rapid transitions between various operational modes. In the conventional SANS mode, three motorized, high-efficiency ³He tube detectors within the detector tank simultaneously cover scattering angles ranging from 0.12° to 35°. In the polarizing SANS mode, a double-V cavity generates highly polarized neutrons, while a high-efficiency ³He polarization analyzer facilitates full polarization analysis. In the VSANS mode, an innovative high-resolution gas electron multiplier (GEM) detector extends the coverage of scattering angles from 0.016° to 0.447°, with a minimum scattering vector of 0.00028 Å⁻¹. The absolute scattering intensities in both the SANS and VSANS modes have been accurately determined using the direct beam technique and the desmear algorithm. The validity of these methods has been confirmed through tests with standard samples, and by comparing the results with those from a benchmark instrument. After being open to the scientific community for one and a half years, the applications and outcomes of the instrument will be discussed.

Speaker: Taisen Zuo (Spallation Neutron Source Science Center) -

14:30

The VESPA Secondary Spectrometer: Conceptual Design Developments 15m

VESPA is a vibrational neutron spectrometer under development at the European Spallation Source. As an indirect-geometry instrument, VESPA will have several key components such as HOPG crystal analysers and beryllium filters in the path of the neutrons between the sample and the detector. These components pose significant engineering challenges in a limited space, such as complex shapes, relatively large components with different operational environments and a staged installation of modules, each with a different orientation with respect to gravity.

One example is the beryllium filters and their supporting systems. For scientific performance the neutron pathlength through the beryllium needs to be maximised for a range of neutron path angles. When accommodating built in collimation blades between the beryllium slices, fitting 8 of these rotated around the beam axis produces some strange shapes, including no perpendicular surfaces. To perform their filtering function, the beryllium filters must be kept below 100K, which puts thermal contraction, heat leaks and risks of condensation into the growing list of design requirements which need to be considered before a concept for their mechanical design can be deemed feasible.

This summary will cover some of the conceptual design developments and ongoing engineering analyses on VESPA that aim to strike balance between the scientific and practical needs of different components in isolation and as part of the wider spectrometer system.Speaker: Helen Popland (European Spallation Source ERIC) -

14:45

FIREPOD: A new thermal high-throughput powder diffractometer at MLZ 15m

The new instrument FIREPOD (FIne REsolution POwder Diffractometer) was successfully transferred from Berlin to Garching as part of a BMBF-funded project. At the MLZ,it will have a ‘second life’ as a dedicated high-throughput instrument, ideally suited for a wide range of fast parametric studies and studies with large sample series. As such, it perfectly complements the group of three unique thermal powder diffractometers located at the SR8 beam tube of the FRM II. Due to the optimised design of the detector, even very bulky sample environments can be used. The scientific focus will be on advanced materials research, including topics with promising industrial applications such as batteries, hydrogen storage, or construction and functional materials under a wide range of conditions, particularly in situ and in operando studies. The details of the instrument design to meet these goals and its forseen capabilies will be presented in detail.

Speakers: Dr Christoph Hauf (TU Munich), Philip Wagner (TU Munich) -

15:00

The Design, Construction and Commissioning of the High-Pressure Neutron Diffractometer at China Spallation Neutron Source 15m

The High-Pressure Neutron Diffractometer (HPND) at China Spallation Neutron Source (CSNS) is a general-purpose neutron diffractometer designed with two operational modes: diffraction and imaging. HPND employs a water moderator that utilizes high neutron energy and provides a neutron flux of up to 107 n/cm2/s. It features a 90-degree detector with an optimal resolution exceeding 0.6%. The two hutches, with flight distances of 22.5 m and 29 m, respectively, accommodate different types of in-situ high-pressure neutron diffraction experiments. The first hutch is equipped with cryostats, furnaces, superconducting magnets, and portable high-pressure cells. The range of temperatures from 1.5 K to 1800 K, magnetic field intensities up to 9 T, and maximum pressures up to 20 GPa facilitate multiple fields-coupling experiments. The second hutch is equipped with a cubic press as well as neutron and X-ray tomography equipment. The cubic press enables experiments under extreme conditions, with pressures reaching 20 GPa and temperatures up to 2000 K. Currently, the commissioning and performance testing of the HPND have been completed. The neutron diffraction experiments conducted under ambient conditions, as well as in-situ variable temperature and high-pressure conditions, have been successfully executed in the HPND. The HPND at CSNS was opened to users in October 2024 and is poised to become an essential tool for investigating the structural evolution of materials under extreme conditions.

Speaker: Le Kang (Spallation Neutron Source Science Center, IHEP, CAS) -

15:15

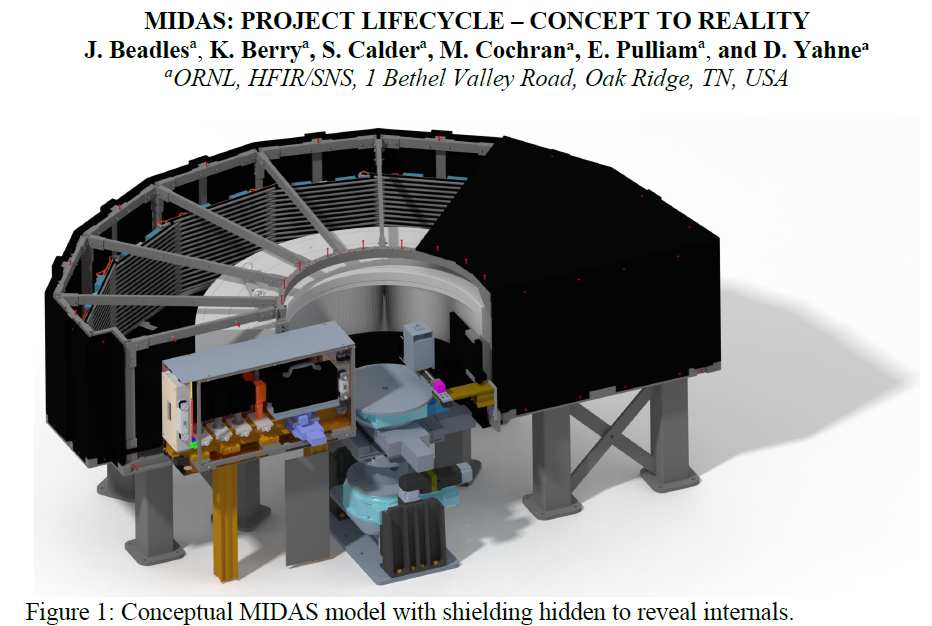

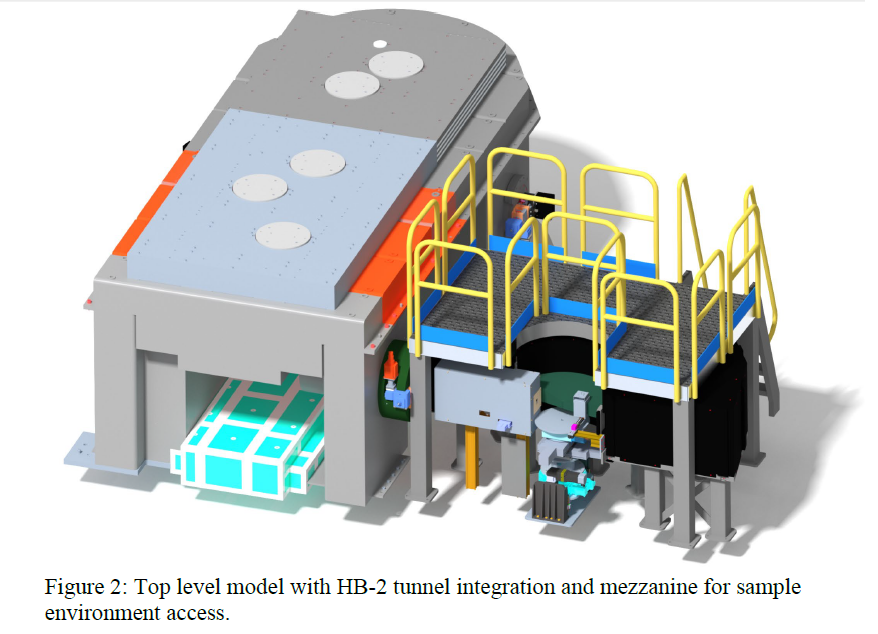

MIDAS: PROJECT LIFECYCLE – CONCEPT TO REALITY 15m

enter code here35 years ago, the Oak Ridge National Laboratory (ORNL) High Flux Isotope Reactor (HFIR) powder diffractometer began life at beam line HB-4 complete with a compliment of 32, vertically oriented, point tube, 3 He detectors arranged radially about the sample position 2.7° apart. It served there for 10 years before being shelved to make way for the Cold Guide Hall project. 17 years ago, the diffractometer was exhumed and rebuilt at the HB-2A beam line, and the detector array was increased to 44 tubes. While the flux improved dramatically, the 2.7° gaps demanded that the entire array be moved across the gaps in 0.05° steps to generate a full diffraction pattern with sufficient overlap between tube signals to reliably fit the data.

This stepping consumed vast amounts of beam time and prevented the diffractometer from performing in-situ studies. To respond to the user community and advisory committee recommendations, several concepts surfaced to meet the requirements of a 150°, gamma insensitive, fixed position detector, that reduced count times and at least maintained the resolution of the HB-2A detector. These features combined with a target budget of $500K for design, procurement, assembly, testing, and installation along with a timeline demanding the project complete before the HFIR Beryllium Reflector Replacement (HBRR) necessitated the use of up to 144 pre-existing tubes inherited from the Intense Pulsed Neutron Source

(IPNS). This resource along with further budgetary uncertainty led to the development of a novel design, the Modular Interdigitated Detector Array System (MIDAS).

The MIDAS instrument upgrade project has been progressing successfully throughout 2025 with final design underway and advanced procurements submitted. The design requires support from the instrument science team, engineering and design, neutronics analysis, data acquisition (DAQ), technical craft and more. The Linear Position Sensitive Detectors (LPSD) will be mounted to the base and interweaved together to form a detector array with full 150° coverage. An oscillating radial collimator, currently being manufactured, will sit between the detector array and sample center. A modular shielding design and support system surrounds the internal

components and will be created using 3D printed molds to fabricate custom B 4 C epoxy casts. Finite Element Analysis (FEA) and structural analysis were used to refine the support system design and base plate requirements. Neutronics analysis optimized the shielding and developed an improved lower profile beam stop. A translation/rotation stage will also be utilized to align a pre-monochromator collimator inside the HB-2 tunnel. Detector electronics and instrument controls will be upgraded to a new EPICS platform and improve user instrument configuration options. The MIDAS upgrade is planned for installation during the Spring 2026 HFIR outage with neutron commissioning to proceed afterwards.

Speaker: Elias Pulliam

Speaker: Elias Pulliam

-

14:00

-

15:30

→

16:00

Coffee 30m

-

16:00

→

16:45

CHOPPERS

-

16:00

Development and Qualification of a High-Speed Chopper Disc Hub 15m

This presentation will discuss the development and qualification of a novel spiral hub designed for high-speed Carbon Fiber Reinforced Polymer (CFRP) Chopper discs on a magnetically levitated SKF spindle. The development of the spiral hub was motivated by previous failures of Chopper disc hubs, which were attributed to high press-fit stress and low-cycle fatigue due to stress cycles during acceleration and deceleration, combined with high load disturbances generated by the magnetic spindle. The spiral hub, manufactured from Titanium alloy, was developed to address these challenges and improve the robustness of the system.

The qualification process involved a series of rigorous tests, including:

- Geometrical measurements and pre-balancing

- Commissioning and fine balancing: Successfully performed up to 354 Hz speed with an acceptable balance level for high-speed operation.

- High-speed operation and clocking measurement: Measuring predictable disc clocking and replicating the expected behavior of the hub.

- Speed cycling test: Performing 50 acceleration and deceleration cycles between 0 and 336 Hz with successful health checks.

- Spindle control loss load measurement and proof load: Validating the hub's strength and robustness against spindle instability, with an estimated maximum radial force of 13 kN.

- The spiral hub successfully resisted the SKF spindle instability at its maximum power, outperforming the old aluminum hub.

The presentation will conclude with a discussion on the future work, including implementing measures to avoid uncontrolled load cases and further measuring the Clocking behaviour of the hub.

Speaker: Mr Xabin Olaskoaga Marijuan (Airbus) -

16:15

From a shaky start to the mass production of choppers - The past and present of chopper delivery at ESS 15m

This talk will focus on the delivery of chopper systems for the ESS instrument suite. It will give an overview of the chopper deliveries at ESS with focus on the in-house designs and developments. The talk will look back on where we started, 13 years ago, and explain how we ended up where we are. The talk looks at development and technical lessons mixed with some personal growth and formative events.

Speaker: Erik Nilsson (European Spallation Source ERIC) -

16:30

Controls and integration of Choppers at ESS 15m

The proper control of neutron choppers is essential for improving the precision, reliability, and efficiency of experiments conducted at neutron research facilities. This presentation contains the various strategies explored at ess for controlling neutron choppers, including data standardization, hardware, and phase control. We will discuss differences in control systems for choppers at ess, such as the integration of data, automation, as well as the challenges faced in maintaining software version, hardware differences/obsolence and reducing system errors. How we aim to deliver better data quality in neutron experiments by optimizing the neutron chopper control. The presentation will also highlight future trends in chopper technology and control systems, including the potential role of artificial intelligence and machine learning for predictive control and system optimization.

Speaker: Andres Quintanilla (ESS)

-

16:00

-

16:45

→

17:30

SHIELDING

-

16:45

Concrete Radiation Shielding for Neutron Facilities: From Design, Manufacturing & Installation Challenges to Early-Stage Sustainability Priorities 15m

Radiation shielding in neutron research facilities presents significant challenges across the full lifecycle from early-stage design to manufacturing and on-site installation. At the European Spallation Source (ESS) in Lund, the engineers faced demanding requirements for structural integrity, geometric precision, lifting coordination, and integration with complex facility layouts. The use of massive concrete blocks (often >3 tons) and strict tolerances underscored the need for interdisciplinary planning and execution. While sustainability was not a primary driver at ESS, this experience highlights the importance of considering environmental impacts and material choices early in future projects to align shielding solutions with broader sustainability goals.

Speaker: Feras Wazzan (ESS) -

17:00

HEAVY METAL 15m

The installation of the shielding and the neutron guides at the FRM II presented a particular challenge due to the limited crane access and the strict safety requirements on site. Simple aids such as air cushions, hydraulic tools and winches were used to overcome these obstacles. The installation of the neutron guides through three buildings required careful consideration of the fire safety, radiological and mechanical requirements. Another challenge was the installation between buildings with different atmospheric pressures. This presentation will look at the detailed strategies and solutions used to successfully overcome these intricate issues. Unexpected situations or interfaces not considered in the design with their respective surprises are not hidden in this talk.

Speaker: Mr Elbio Calzada (Forschungs-Neutronenquelle Heinz Maier-Leibnitz (FRM II)) -

17:15

Advances in Additive Manufacturing for Complex Neutron Shielding Components 15m

Additive Manufacturing (AM), with its capability to produce complex geometries, has been established as a viable method for fabricating neutron shielding components from composite filaments containing materials such as B$_4$C suspended in a thermoplastic matrix. In this work, a novel strategy for AM was employed, focusing on the development of a collimator with a blade thickness of 0.5mm using filaments containing 40 wt% B$_4$C. Primary challenges associated with the use of highly loaded filaments in combination with thin-walled structures, including stringing reduction and uniform blade thickness retention, were addressed. Results from neutron imaging demonstrate that the applied strategy led to the elimination of visible stringing within the image, maintenance of even blade thicknesses over the entire collimator, and sharp corners, in contrast to collimators produced without modifications to the manufacturing process.

Speaker: Dr Rafael Martin Heeb (STFC Rutherford Appleton Laboratory)

-

16:45

-

17:30

→

19:30

DENIM Challenge: DENIM Challenge - Cheese and wine

-

08:00

→

09:00

-

-

08:30

→

09:00

Coffee 30m

-

09:00

→

09:45

Knowledge transfer: how to and why you should do it 45mSpeaker: iain sutton (ESS)

-

09:45

→

10:30

Lesson Learned II: LESSON LEARNED

-

09:45

From Commissioning Challenges to Operational Readiness: Lessons Learned from Medium Speed Choppers at the ESS 15m

The European Spallation Source (ESS) represents one of the most ambitious scientific infrastructure projects in Europe, bringing together a wide community of institutes, funding bodies, and experts to deliver the next generation of neutron science. Among the key subsystems enabling world-class performance are the neutron chopper systems — over 100 precision-engineered devices designed to manipulate the neutron beam in both time and space to meet diverse scientific demands.

We will share the lessons learned from the commissioning process, including optimizations in balancing methodology, mitigation of vibration-related issues, and integration within the broader ESS control environment. These insights have not only enabled successful deployment on BIFROST and other instruments but are shaping best practices for future chopper commissioning across ESS.

As ESS advances toward operational readiness, with 15 neutron scattering instruments being prepared in parallel, the experience gained from BIFROST and other instruments provides a critical foundation for ensuring reliable, high-performance chopper systems for the next generation of neutron science.Speaker: Nikolaos Tsapatsaris (European Spallation Source) -

10:00

Lesson learned during the installation of a complex neutron guide system 15m

The H15 neutron guide at the ILL is a complex system delivering neutrons to 5 new or fully renovated instruments.

Due to its dimensions, in particular before the first split,the reduced places for the instruments and their demands in terms of beam conditioning (polarization, monochromators, chopper systems, etc.), the installation process has been full of surprises. Reactivity and quick porblem solving have been a necessary tool on the building site to deliver astate of the art neutron guide.Speaker: benjamin giroud (Institut Laue Langevin) -

10:15

The use of standard industrial motion components in radiation and vacuum environment of Neutron Instruments 15m

Neutron Instruments on spallation sources have very particular environmental conditions in their instrument zone. Typically vacuum and radiation requirements are not as demanding as on applications at other radiation facilities like synchrotrons or inside reactors. Even with high flux sources some well selected standard industrial motion components like motors, switches, cables and connectors can be used, especially in the applications around the sample area.

In this contribution we present the selection of these components on ESS Neutron Instruments suitable for these kinds of environment. We will list parts, application, the environment and the basis of our selection. This could be values in data sheets, an evaluation of the material of the component, tests or a recommendation from suppliers or in-kind partners. We also present typical pitfalls to avoid when choosing certain parts and materials. It will help design engineers to better understand the selection criteria and avoid the use of expensive specialized parts if not needed.

Speaker: Thomas Gahl (ESS Lund)

-

09:45

-

10:30

→

11:00

Coffee 30m

-

11:00

→

12:30

INSTRUMENTS AND PROJECTS

-

11:00

New engineering tool for neutron instrument design: "Cryomagnet Strayfield Impact" 15m

Many neutron instruments use strong magnetic fields as part of their standard sample environment. Such magnetic fields are currently generated with cryomagnets, which typically produce a strong stray field due to their design. Neutron instrument components such as the sample stage, motors and electronics are often exposed to this magnetic stray field and can be damaged as a result. Additionally, strong attractive forces can act on the cryomagnet and cause it to quench. This occurs when steel parts are in the stray field and a maximum permissible force of attraction is exceeded. Quenching can be prevented with proper design measures. Therefore, when designing neutron instruments, magnetic fields and their effects should be taken into account.

In order to quickly identify potential damage to motors and electronics, design engineers need a tool that allows them to calculate local magnetic fields during instrument design. The tool should also be able to calculate magnetic attraction forces to predict or prevent quenching of the cryomagnet. Unfortunately, good magnetic field calculation programs are usually difficult to use and require specialized knowledge. Moreover, the development of a suitable calculation model is time-consuming.

To address the aforementioned gap in the designer's toolbox, an easy-to-use software application is presented. It is a so-called COMSOL app that was developed at LIN* in 2024. Using the finite element method, it quickly and efficiently calculates magnetic fields and their effects. The tool is tailored to neutron instrumentation.

*Laboratory for Neutron and Muon Instrumentation (LIN), Paul Scherrer Institut, Switzerland

Speaker: Lothar Holitzner (Paul Scherrer Institut PSI) -

11:15

Background reduction by use of a Sapphire single crystal filter 15m

Fast neutron background poses a significant limitation to the signal-to-noise ratio in many neutron instruments. At the BOA beamline at the Swiss spallation neutron source SINQ, cold neutrons are reflected out of the direct line of sight from the source using a supermirror bender, while fast neutrons (>1 MeV) propagate through the beamline shielding due to their high penetration capability. To attenuate this fast neutron component, we investigated the use of a sapphire single-crystal filter.

The spatial and spectral characteristics of the fast neutron beam were determined using a fast neutron scintillator coupled to a CCD camera and an extended range Bonner sphere spectrometer. In the setup, cold neutrons were shielded using a borated neutron absorber to observe only the fast neutron component of the spectrum. Beam spectra were measured in and out of beam with and without the sapphire filter in place and analyzed with Bayesian parameter estimation. The effect of the sapphire filter on the cold and thermal components were characterized with an unshielded time-of-flight setup. MCNP and McStas simulations were performed for the BOA beamline to compare and proof the filter’s attenuation across the full energy range.

The sapphire filter demonstrated significant attenuation of epithermal and fast neutrons in the beam, while cold neutrons were only mildly attenuated. The measured attenuation in the beam is in good agreement with simulations of the sapphire filter across the energy spectrum from 25 meV to 200 MeV. Implementation of the filter in the beamline bunker led to a measurable decrease in neutron background which agrees with the simulations, improving experimental conditions and signal-to-noise ratio.

These results demonstrate that sapphire filters are a viable option for reduction of fast neutron background, enabling more efficient measurements by an improved signal-to-noise ratios in neutron scattering applications.Speaker: Daniel Zeitz (Paul Scherrer Institute) -

11:30

NEW POSSIBILITIES WITH 3D PRINTING AND INNOVATIVE FILAMENTS 15m

Building neutron optics devices, including neutron guides, necessitates effective shielding of construction materials against neutron radiation (thermal and cold neutrons) to prevent material damage such as embrittlement. Additionally, neutron radiation escaping from these devices is disturbing the neutron science experiment as so-called background.

Common shielding materials in neutron science include boron, cadmium, and gadolinium. Boron-based materials are preferred because they produce only low-energy gamma radiation, which can be easily shielded. However, boron carbide (B₄C) materials are very hard and rather expensive to process. The present standard shielding material, BORAL, consists of a matrix of B₄C in aluminum, with B₄C enrichment ranging from 20 to 35 wt%.

To replace BORAL, we have developed boron-enriched filaments for 3D printing applications using FFF printing technology. These filaments incorporate boron carbide (B₄C) at concentrations of 25-45 wt%. The B₄C is embedded within a plastic matrix containing approximately 10 wt% hydrogen, thereby enhancing the shielding properties of the material. A disadvantage of B₄C is its carbon content, which is highly abrasive, leading to frequent replacement of 3D printer components. To mitigate this, we developed a novel filament containing 25 wt% of boron 10 isotope, which is less abrasive and offers better shielding performance.

In addition, we have manufactured filaments containing up to 40 wt% gadolinium oxide. To counteract the secondary gamma radiation emitted, we created composite filaments that contain both B₄C and tungsten, with enrichment levels reaching up to 80 wt%.

With these filaments we are aiming to produce various types of collimators and flight tubes. Initial prototypes have been manufactured and tested.

We will present the progress of the last year and of our developments and applications, including the limiting factors and challenges associated with the 3D printing technology. First prototypes are installed at Poldi, Neutra, SANS- LLB, DMC and CAMEA.Speaker: Ms Andrea Plank (Paul Scherrer Institut) -

11:45

Moving, re-designing and upgrading the T3 neutron optics test instrument at the ILL 15m

At the ILL Multilayer Group, we coat multilayers (including supermirrrors) and produce optical devices like polarisers, wavelength filters and others. Having access to a reliable and performing characterization instrument is compulsory for this activity. The group owns a test instrument named T3, which was stopped in 2021 due to a large upgrade of the guide hall. The instrument moved to a new position on the new H15 guide. We took advantage of this imposed move to re-think its design in order to upgrade its capabilities, despite a constrained budget.

T3 is basically a cold monochromatic angle-dispersive polarized neutron reflectometer, which we also use for various measurements and tests in the field of neutron optics instrumentation. The essential requirement was to allow the measurement of polarizing mirrors in a reliable, reproducible and if possible even better way than before. Another vital one is to characterize assembled optical components in real conditions, typically polarizing benders with their mechanics and magnetic circuit. Other types of optical device developments would need a similar mode in order to be characterized: focusing mirrors, assembled guides, nested optics, etc. As an additional feature, the possibility to characterize monochromator crystals produced by the ILL Monochromator Group was considered. This Group runs test instruments using thermal wavelengths, but none of them is in the cold range.

We will give an overview of the design choices, from the most traditional to the most original ones. We will then outline the execution of the project, during which we seized a few opportunities and relied on cooperation within the ILL to optimize the efficiency of our available budget. The instrument is now being commissioned and run, which will allow us to report some measured performance, which are rather outstanding for a test instrument. We will then address the foreseen improvements and modifications, in relation to the initial requirements.Speaker: Dr Thierry Bigault (ILL) -

12:00

THE DEVELOPMENT OF HIGH TEMPERATURE & PRESSURE SAMPLE ENVIRONMENT FOR NEUTRON REFLECTOEMTRY 15m

The ISIS INTER beamline is a high-flux neutron reflectometer capable of achieving high resolution and fast measurement speeds. A catalytic reaction study involving ionic liquids (ILs) has been proposed to take advantage of this capability. This area of research requires a challenging bench-top sample environment chamber that is compatible with pressurised flammable gases (up to 145 bar H₂, H₂/CO mixtures, or H₂ and alkenes) and can operate at controlled elevated temperatures (ambient to 200 °C). Such applications pose a significant fire hazard on the beamline, which was not originally designed for explosive gas atmospheres. The construction of this system therefore requires a high level of design safety to mitigate operational hazards. This presentation introduces the ongoing design work, including concepts, stress and thermal analyses, heating methods, control strategies, and protection measures. It also discusses interpretations of relevant codes and regulations, with the aim of sharing experience and knowledge with colleagues attending DENIM.

Speaker: Xiao Wang (UKRI, STFC, ISIS neutron and muon Facility) -

12:15

Recent achievements in advanced diffractive optics for neutron monochromators at ILL 15m

Within the Endurance Phase 1 projects, several new monochromators have been developed, covering the complete process from crystal growth to device integration, with first results already obtained on ILL instruments. Major achievements include large double-focusing HOPG monochromators for the D007 diffuse scattering spectrometer and the SHARPER time-of-flight spectrometer, as well as a new HOPG monochromator for D10+. Mosaic CaF₂ crystals, produced at the ILL, have been successfully applied in a temperature-gradient monochromator for the thermal neutron backscattering spectrometer IN13. Large single crystals grown in-house provide copper crystals with controlled mosaic distribution, enabling highly efficient monochromators such as those for the PANTHER spectrometer and the upgraded D10+ diffractometer.

In parallel, new fabrication techniques for advanced neutron optics using perfect Si single crystals have been established. These methods allow the production of high-quality bent Si(111) crystals, without mechanical support, thereby enabling the development of innovative optical designs. A key application is the MARMOT analyzer system for the ThALES spectrometer, currently under construction, which employs a unique focusing geometry to provide simultaneous analysis over a quasi-continuous energy range (3.5–7 meV) and a wide 75° angular coverage, representing a major step forward in multiplexed neutron spectroscopy.Speaker: Pierre Courtois (Institut Laue Langevin)

-

11:00

-

12:30

→

14:00

Lunch 1h 30m

-

14:00

→

15:30

POSTER SESSION: Sponsors and Poster session

-

14:01

The Role of the Instrument Operations Engineer (IOE) at ESS 1m

The Instrument Operations Engineer (IOE) plays a central and hands-on role in ensuring the readiness, reliability, and long-term functionality of neutron scattering instruments at the European Spallation Source (ESS). Working closely with scientists, engineers, and technicians, the IOE contributes throughout the full lifecycle of an instrument, from installation and commissioning to routine operation and upgrades.

During the pre-operational phase, the IOE assists with installation, supports component testing at partner facilities, and helps develop and execute commissioning plans. The IOE tasks also involve preparing safety documentation and contributing to mechanical design improvements. As instruments transition to hot commissioning, the IOE becomes a key technical contact, responsible for coordinating maintenance, managing engineering records, and ensuring systems operate within design parameters.

Once in operation, the IOE supports scientific experiments by configuring instruments, assisting with sample environments, and maintaining safety standards. Involves troubleshooting, planning upgrades, and collaborating with specialized technical teams to adapt instruments to evolving research needs.

Comparable roles exist at other leading neutron facilities worldwide, though they may be titled differently. At the Spallation Neutron Source (SNS) in the USA, similar responsibilities are carried out by Instrument Scientists; at ISIS Neutron and Muon Source in the UK, Beamline Scientists and Operations Technicians fulfill overlapping functions; and at J-PARC in Japan, Instrument Engineers and Facility Coordinators take on analogous duties. Despite variations in naming and organizational structure, these roles share a common mission: to ensure the safe, efficient, and scientifically productive operation of complex neutron instrumentation.

By combining engineering expertise with operational insight, the IOE at ESS exemplifies this global standard, ensuring that instruments perform reliably and safely, enabling high-quality scientific output and a seamless user experience.

Speaker: Tamires GALLO (ESS - European Spallation Source) -

14:02

Development of High-Pressure Sample Environment Equipment for Neutron Scattering at CSNS 1m

High-pressure sample environments are essential for neutron scattering studies under extreme conditions. At the China Spallation Neutron Source (CSNS), a range of high-pressure loading systems are currently under development, including gas-driven and hydraulic equipment with target pressure ranges exceeding 600 MPa. These systems are designed to support in-situ structural and magnetic measurements. For research on gas storage and adsorption materials, a gas adsorption analyzer is being integrated to enable real-time monitoring of adsorption behavior. In addition, a Paris–Edinburgh press coupled with a low-temperature cryostat is under construction, aiming to support high-pressure neutron experiments down to 150 K. These systems will be gradually deployed across multiple beamlines, with continued efforts toward automation and compatibility to better serve the growing neutron user community.

Speaker: Mr Bin Li (CSNS) -

14:03

INSTALLATION AND INITIAL COMMISSIONING OF THE SAMPLE STAGE AT RESEDA 1m

As part of the experiments at RESEDA, scientists need the ability to align the sample to the neutron beamline according to the experimental specifications and to capture a broader spectrum within the sample by moving the stages.

In the contribution, we describe the setup of the sample stage according to the scientific specifications, the mechanical attachment to the marble floor, the control unit for controlling the stepper motors, encoders and limit switches on the sample stage, as well as the commissioning process with a risk assessment.

We also provide the details on the interface between the sample stage and the control unit. The settings of the communication for the Phytron phymotion (control unit) using the Phytron PhyLogic software is also an interesting part to operate the sample stage.

Speaker: Christian Fuchs (TU München Forschungs- Neutronenquelle Heinz Maier-Leibnitz) -

14:04

COMPACT TURNTABLE FOR THE HELMHOLTZ-COILS FOR POLARIZED COLD NEUTRON TRIPLE-AXIS SPECTROMETER KOMPASS AT THE MLZ 1m

For specific experiments at the new cold neutron triple axis spectrometer KOMPASS, a precisely aligned magnetic field is required. This field is generated using a Helmholtz coil system, which allows controlled rotation of the magnetic field in space. To prevent interference from the neutron reflecting sample striking the coil segments, the system must be rotatable out of the neutron beam. A custom-designed rotary platform was developed specifically for KOMPASS to meet this need. Due to strict requirements for low magnetic interference and a compact design, commercially available rotary stages were not suitable.

My poster introduces the development process of the rotary adapter. Which essentially consists of the rotation mechanism being driven by a stepper motor via a toothed belt and having a specially developed bearing system that is optimized for low height and minimal magnetic influence. There were some challenges encountered during assembly and initial testing, which are discussed in more detail in the poster.

Speaker: Manuel Mueller (FRM II Forschungs-Neutronenquelle Heinz Maier-Leibnitz) -

14:05

Relocation and upgrade of the cold triple axis spectrometer FLEXX at MLZ, Munich: Larmor diffraction and inelastic scattering 1m

The cold triple-axis spectrometer (TAS) FLEXX at HZB was a well-designed and upgraded instrument [1-4]. There was a strong wish that this excellent instrument should be preserved for the community. One attractive gap in the present instrumentation suite of MLZ, is the Larmor-diffraction technique [5-6] (LD) and, as a natural extension, cold neutron resonant spin echo (NRSE). TAS comes at no extra cost, as it is the main backbone of such an instrument.

The instrument will be placed on a cold neutron guide and essentially merged with the former MIRA TAS. Further, new developments are under way to allow for application of magnetic fields at the sample, hitherto not possible [7-9]. This opens up new vistas in the exploration of materials. A last attractive option is the possibility to combine high magnetic fields together with cold TAS.

The monochromator shielding of FLEXX is strengthened to enable its usage at the FRM-II reactor.

A new monochromator mechanics is designed in order to allow for double focussing optics, but in the same time leave the beam unaffected for downstream instruments.

The sample table is completely freshly made in order to allow heavy sample environment, up to 1000 kg. A multi-analyser will be finally employed to allow for quick surveys in (Q,ω) space.[1] M. Skoulatos et al., NIMA 647, 100 (2011).

[2] M.D. Le et al., Nucl. Instr. Meth. Phys. Res. A 729, 220 (2013).

[3] F. Groitl et al., Rev. Sci. Instrum. 86 025110 (2015).

[4] K. Habicht et al., EPJ Web of Conferences 83, 03007 (2015).

[5] M.T. Rekveldt, Jour. Appl. Phys. 84, 31 (1998).

[6] M.T. Rekveldt et al., Europhys. Lett. 54, 342 (2001).

[7] Neutron Spin Echo - Proceedings of a Laue-Langevin Institut Workshop, Grenoble, Springer- Verlag, Ed:

F. Mezei (1980).

[8] M.T Rekveldt et al., Jour. Appl. Cryst. 47, 436 (2014).

[9] K. Habicht, “Neutron-Resonance Spin-Echo Spectroscopy: A High Resolution Look at Dispersive Excitations”, Habilitation, University of Potsdam (2016).Speaker: Daniel Zahreddin (FRM II) -

14:06

Intensive Re-design of a FERMI Neutron Chopper 1m

DENIM XIV Abstract – Poster : Intensive Re-design of a FERMI Neutron Chopper.

Peter Galsworthy – peter.galsworthy@stfc.ac.uk

ISIS Neutron and Muon Source, Rutherford Appleton Laboratory, Harwell Campus, Didcot, OX11 0QX

Following a major failure of a FERMI Neutron Chopper at high speed, the ISIS Neutron Chopper Design team started an investigation into the likely cause of the failure and an intensive re-design programme. This poster with show the details of both these stages and lessons learnt.Speaker: Peter Galsworthy (STFC - ISIS) -

14:07

DEVELOPMENT OF NEW PASTIS COILS BASED ON A HALBACH RING PAIR 1m

The existing XYZ field system for PASTIS at TOPAS (FRM-2) has several disadvantages.

It has residual blind spots, a limited vertical acceptance angle, and limited access for 3He cell installation.

To solve these disadvantages, a prototype of a Halbach ring pair for the horizontal X and Y

fields, is currently under development. This prototype will be used with a Helmholtz coil for the Z field to provide a holding field for the wide-angle 3He analyzer cells. Two Halbach rings are planned, each of which will provide a field in the horizontal plane. The rings can be rotated relative to each other to cancel the horizontal field.

The goal of this project is to develop a prototype of a Halbach ring pair and a Helmholtz coil that is compatible with the TOPAS detector tank and sample environment geometry. This will enable us to determine the feasibility of the mechanical design and whether the actual field gradients measured in our magnet laboratory align with the developed FEM models.

Additionally, we can directly test the T1 lifetime of the polarized 3He cell.Speaker: Jos Daemen (Forschungszentrum Jülich, ITE) -

14:08

Electrical Design of Super MuSR Instrument 1m

This poster explores the electrical engineering behind the Super MuSR Muon instrument, emphasising its unique requirements compared to Neutron instruments at ISIS. Super MuSR incorporates multiple precision magnets, each requiring dedicated power supplies and control systems. This introduces significant complexity in power distribution, control architecture, and system integration. Compared to neutron instruments, which require extensive shielding to manage high-energy particle interactions, muon instruments like Super MuSR benefit from significantly reduced shielding demands. This enables greater design flexibility in the electrical infrastructure.

Attendees will gain insight into how tailored electrical design enables the scientific and operational goals of Super MuSR, and how these design choices contribute to the evolving engineering practices at ISIS Neutron and Muon Source.Speaker: Mr Luke Afford -

14:09

Taking Control: Remote Pendants at ISIS 1m

At ISIS, many instruments with motion systems can only be operated from a fixed computer terminal that may have limited visibility of the experimental setup. For IMAT, this posed a challenge, as scientists often need to visually align hardware relative to the sample during setup. To address this, a mobile pendant was developed to allow safe and ergonomic remote control of the motion equipment from within the blockhouse.

The project involved identifying and evaluating potential solutions that could meet strict safety requirements, integrate seamlessly with the existing TwinCAT control environment, and provide a comfortable user experience. Regular meetings with end users throughout the design cycle, combined with independent research, ensure that the final solution will meet scientific needs while maintaining operational safety.

This poster presents the development journey, highlighting the key challenges and decisions involved, and demonstrates how the resulting remote-control solution for IMAT can be standardised and adapted for other beamlines in the future.

Speaker: Michael Lovell -

14:10

Design and Integration of the HEIMDAL Front End Chopper System at the European Spallation Source 1m

The HEIMDAL thermal chopper system consists of two main sub-systems: the in-bunker Front End chopper system and the out-of-bunker TFOC chopper system. The poster is about the more complex in-bunker system which is a new design compared to the previous systems the ESS Neutron Chopper Group (NCG) has developed so far. The system houses two separate mechanical assemblies which are integrated onto a common plate along with two sets of neutron guides – thermal and cold. The whole module is located in the fully remote handling area of the bunker and the chopper assemblies need to be remotely extractable and re-installable. At this stage all of the mechanical parts are delivered to ESS and the chopper integration is ongoing.

Speaker: Ioannis Apostolidis (European Spallation Source) -

14:11

Zoom SANS instrument - top loading platform 1m

Design of custom personal platform, to allow loading of large samples from top.

Addition of new PPS equipment and modification of existing ones.

Issues with installation.Speaker: Wojciech Paterski -

14:12

Mechanical Design of the Beam-Splitting for Neutron Backscattering Spectrometer in CSNS 1m

The neutron backscattering spectrometer (NUBS) currently under construction at China Spallation Neutron Source (CSNS) Phase II project will become the facility's longest spectrometer, featuring a 90-meter moderator-to-sample distance. Utilizing Channel 10, this spectrometer implements an beam-splitting guide design to simultaneously accommodate the NUBS operation and a future 10A beamline, requiring specialized mechanical solutions to overcome spatial constraints in both the first shutter and bulk insert regions.

Key design features include:

1. Dimensional specifications with NUBS guides measuring 60 × 90 mm (W×H) and 10A beamline guides at 25 × 50 mm, arranged with a 1.8° separation angle (0.6° deflection for NUBS away from Channel 9 versus 1.2° opposite deflection for 10A).

2. First shutter integration:

(1) Initial 500 mm shared tapered guide section

(2) Monolithic assembly combining NUBS guide, 10A guide, and shared section

(3) Prefabricated as complete unit by SwissNeutronics for simplified alignment in CSNS

3. Bulk insert configuration:

(1) Single-unit installation and alignment

(2) Fixed NUBS guide as reference

(3) 10A guide equipped with precision height/horizontal adjustment mechanisms

(4) Offline calibration ensuring proper relative positioning between NUBS guide and 10A guide before final installation

4. Post-bulk insert arrangement:

(1) Fully separated guide systems between NUBS guide and 10A

(2) Independent adjustment mechanisms for each guide

Installation and alignment of these systems are scheduled for completion in summer 2025.Speakers: Mr Yanyan Wu (Institute of High Energy Physics, Chinese Academy of Sciences), xiao songwen (Institute of High Energy Physics, Chinese Academy of Sciences) -

14:13

Design of a Circular Neutron Detector 1m

An overview of a novel 2m diameter neutron detector being built at ISIS, which uses curved wavelength shifting fibres arranged to form concentric circles.

Speaker: james prince (Isis, RAL, STFC) -

14:14

Using an Industrial Robot for High-Precision Sample Manipulation at the Neutron Diffractometer STRESS-SPEC 1m

Materials and components with intricate geometries, such as from additive manufacturing (AM), require highly flexible sample positioning systems during diffraction experiments. The STRESS-SPEC group at Heinz Maier-Leibnitz Zentrum (MLZ), Germany, has pioneered the use of industrial robots [1, 2] to enhance sample handling and positioning at neutron diffractometers. While these robots may easily position the sample in the desired directions and orientations, their absolute accuracy of up to ±0.5 mm has been insufficient for this type of precise local measurements. To allow accurate full strain tensor determination and centering of local texture measurements, a positioning accuracy within 10% of the gauge volume size is required, with may be as small as 1 mm³ on modern neutron diffractometers [3]. To address this limitation, we have upgraded the STRESS-SPEC robotic system with an optical metrology setup that actively tracks and corrects the sample position with a spatial accuracy of better than 50 μm. Here we will present the complete measurement process chain for this improved sample positioning system.

Furthermore, a versatile laser furnace with a large neutron acceptance angle for temperatures up to 1200°C and a lightweight tensile testing machine are currently being built to be mounted on the robot flange. Together with the optical feedback system, the most common experimental scenarios can then be covered in a semi-automated measurement environment.

Speaker: Mr Lijiu Wang (MLZ - TUM) -

14:15

FAT-SAT-Tools, accelerating acceptance testing 1m

The ESS facility has been receiving a large number of subsystems to be installed across various instruments. The MCA group has faced the challenge of performing numerous acceptance tests for all motion-related devices within a short period of time. To ensure timely delivery and maintain a high-quality standard, the MCA group has developed a testing method based on ISO standards and automated testing tools.

The subsystems consist of motion equipment powered by motors or pneumatic actuators, such as linear stages, rotary stages, slits systems, and pneumatic shutters. The subsystems are connected to test crates, which are prepared for quick connection. Software has been developed to control the motors or actuators, and a python script runs automated tests, moving the devices to various positions while simultaneously acquiring and saving time stamped data related to position and switches. Once the test is complete, another script processes the logged data and generates a detailed report containing all the necessary results to determine whether the equipment meets installation requirements.

These results are based on the ISO 230-2 standard, which specifies the performance variables required for motion systems. The purpose of ISO 230 is to standardize methods for testing the accuracy of machine tools. Specifically, this section of ISO 230 outlines test procedures to evaluate the accuracy and repeatability of positioning for numerically controlled axes.

Finally, the test results are added to the official test report and uploaded to CHESS for approval.Speaker: Ruben Martinez Garcia -

14:16

Installation and commissioning of Multi-Blade detector at ESS Test Beam Line facility 1m

The European Spallation Source is a multi-disciplinary research facility which will deliver intense pulsed neutron beams to enable groundbreaking studies of materials in various scientific fields, including physics, chemistry, biology, and engineering. The first facility which will receive neutrons at ESS is the Test Beamline (TBL). It is designed to validate the successful commissioning of the ESS spallation source. Positioned in direct line of sight to the neutron moderator, TBL enables the characterisation of moderator using advanced suit of five detectors which will provide precise data to characterise neutron energy distribution across the moderator and neutron pulse shape for the purpose of calibration of neutron beam delivered to instruments.

The Multi-Blade (MB), a Boron-10-based neutron detector, is designed to address the demanding requirements for spatial resolution and counting rate capability. This detector is one of these five detectors that is going to be commissioned with the first production of thermal neutrons at ESS. In my poster I present the stages of installation, test, integration and commissioning of MultiBlade detector at TBL.

Speaker: Farnaz Ghazi Moradi (European Spallation Source-ERIC) -

14:17

ESS Chopper Assembly and Development Lessons 1m

With the European Spallation Source approaching the milestone of beam on target, our team continues to work diligently on the development and construction of chopper systems. Over the past two years alone, we have successfully built and tested nine systems and are currently in the process of assembling five more.

Each system demands significant time and effort, presenting a range of unique and evolving challenges. In my presentation, I will outline the key steps involved in assembling these systems, highlight some of the difficulties we encounter, and discuss how we apply lessons learned from previous builds to enhance and streamline the assembly process for future choppers.Speaker: Benjamin Unwin (European Spallation Source ERIC) -

14:18

Setting up heavy shielding elements outside the overhead crane area by means of a rail system and the associated challenges 1m

When heavy shielding elements need to be placed outside the area accessible to cranes, installing a rail system can provide an effective solution. This poster outlines our practical experience with such a setup, highlighting the main challenges encountered and valuable lessons learned to help others avoid common pitfalls.

A brief overview of our rail system is presented, along with discussions of several common technical challenges encountered during installation and operation. These include alignment difficulties due to uneven ground and inconsistent rail heights, as well as complications arising from repurposing neighbouring shielding elements, such as issues with positioning accuracy, existing weld seams and an oil filling that must not be heated during welding.

Additionally, the ceiling bar transport trolley is presented, highlighting issues such as weld seams on the rolling surface, missing crane hooks, non-removable fall protection, compromised height adjustment mechanisms and absent braking systems.

Finally, issues with the roller units of the ceiling bars, such as corroded threads, unauthorised design modifications by contractors, collisions with adjacent shielding elements and the importance of careful tool usage are addressed.

By sharing these insights, we aim to support the more efficient and safer implementation of rail-based shielding systems in constrained environments.

Speakers: Kathrin Lehmann, Ralf Friedmann (FRM II) -

14:19

ESS Common Motion Control Project for Neutron Instruments 1m

The ESS neutron instrument suite requires a large number of cabinets and cables for motion applications. The Motion Control and Automation Group (MCAG) standardization effort of the motion components across the facility ensures that the quality and reliability requirements are met. This standardization directly impacts the operation, maintenance, and upgrade of the systems.

During the final critical design review of the first instruments, MCAG identified an opportunity to further improve the quality, reliability, and compatibility of the motion control systems. To ease the transition from supporting the instruments to taking ownership of the instrument itself , with a focus on the operation phase, the Common Motion Control and Automation Project (CMCA) for the instruments was implemented. CMCA encompasses the motion control cabinets, the cables from cabinet to subsystem and motion safety of the neutron instruments.

This contribution describes the approach and processes used to achieve the expected quality, reliability, and compatibility, as well as a detailed description of the deliverables provided by the project.Speaker: Federico Rojas (European Spallation Source ERIC) -

14:20

Ensuring Beamline Safety at ISIS: A PPS Approach Compliant with IEC 62061 1m

Beamline operations at the ISIS Neutron and Muon Source demand rigorous safety measures to protect personnel primarily from radiological hazards and, other identified hazards. The Personnel Protection Systems are developed in alignment with SC40 (Interlocks for Personnel and Enviromental Protection) and IEC 62061:2021 (Safety of machinery - Functional safety of safety-related control systems) add full title of the standard. By following the ISIS Interlock Management Plan through the full lifecycle of the safety interlock system development, compliance is ensured. The system architecture supports consistent safety performance across diverse experimental setups by using certified safety PLCs, redundant interlocks, and controlled access protocols.

Speaker: Guilherme Avila Farenzena (STFC) -

14:21

Radiation Effects on Various Materials used in Neutron Scattering Facilities 1m

Over the nearly 20 years of operation of the OPAL reactor and Neutron Beam Instruments a number of materials have been impacted by radiation. This poster will cover the types of materials and what mitigation strategies and tests we have come up with to deal with these challenges.

Materials that have seen damage from radiation include Neutron Guide delamination, Loss of Magnetism in Laser tracker target nests, electronic parts failures and oily residue from cabling in vacuum chambers.

Oily residue in vacuum tanks caused by the cable insulation breakdowns are now well controlled with cold traps.

We began a process of testing some materials in very high radiation fields prior to installation and the results will be presented.

Speaker: Mr Lee Stan (Australian Nuclear Science and Technology Organisation) -

14:22

Thermal Neutron Three-Axes Spectrometer PUMA: Recent Instrumentation Development 1m

PUMA is the thermal neutron three-axes spectrometer (TAS) at MLZ. Owing to the dynamical double-focusing technique and compact neutron optics with wide beam divergence, PUMA is mainly characterized as one of the highest neutron flux TAS. The typical scientific applications of PUMA are studies of phonons and magnons. Since 2021, PUMA is co-operated by the Institute of Quantum Materials and Technologies of the Karlsruhe Institute of Technology (IQMT, KIT) and the Technical University of Munich (TUM) within the framework of a collaboration contract. As joint instrumentation project, a nested mirror optics (NMO) focusing technique is being developed to further enhance the signal-to-noise ratio in measurements with a smaller sample size (less than 5 x 5 mm). This new optics will also help us to reduce background signals from a massive sample environment such as a magnet or high-pressure cell.

Speaker: Yongjin Kim (FRM II) -

14:23

Critical Design Considerations for Limit Switch Actuators in Precision Motion Control Systems 1m

The reliable performance of limit switch actuators is essential for achieving both safe operation and long-term durability in precision positioning control systems. Several factors and selection criteria must be carefully addressed during the different stages of the system design. This work presents the critical design decisions required to ensure safety, accuracy, and durability in limit switch actuators for precision motion control systems.

From a safety perspective, redundant arrangements such as overtravel limit switches and fail-safe wiring configurations are emphasized. For accuracy, actuator geometry, switch repeatability, and debounce logic are discussed. In terms of durability, material selection, actuator wear, and environmental protection are key. By addressing these factors, engineers can ensure reliable operation and long service life of motion control systems.Speaker: Mr Hussein Al-Sallami -

14:24

Development of T0 choppers for ODIN and HEIMDAL instruments at the European Spallation Source 1m

The T0 chopper system is designed to block fast neutrons and gamma radiation from the prompt source pulse. To attenuate the fast neutrons to the required level, the T0 chopper places an attenuator mass of high cross-section materials in the neutron beam. The arrangement of materials is optimised to serve the purpose and consists of boron carbide, tungsten alloy, copper-chromium alloy and nickel-chromium alloy. The T0 rotor weighs 375 kg overall and runs at 14 or 28 Hz, supported by traditional bearings and driven by a 6.5 kW brushless motor. The poster shows the current status of the project and aims to illustrate the critical design features of the chopper.

Speaker: Massimiliano Di Nardo -

14:25

As-build process for accelerator, target and neutron scattering systems at European Spallation Source 1m

As the European Spallation Source (ESS) advances through construction and commissioning in Lund, Sweden, it is crucial to evaluate the status of each system and ensure that 3D models and 2D drawings accurately represent on-site conditions. The as-built process for mechanical systems is fundamental in maintaining accuracy, ensuring compliance, and reducing risks while easing future maintenance. Achieving this requires strong collaboration between project management, design, engineering, and installation teams to track modifications, resolve discrepancies, and systematically document changes. Data from 3D scans, manufacturer documentation, NCRs, and project records are utilized to compare the built structures with the original designs.

This contribution outlines the as-built process, key stakeholders, and their roles at different project stages. Additionally, it presents a proof of concept showcasing the benefits and challenges of its implementation at ESS.Speakers: Antoine LEPINE (European Spallation Source ERIC), Luca Sagliano (European Spallation Source) -

14:26

Bridging Science and Engineering: Lessons for Next-Generation Research Facilities 1m

The successful delivery of large-scale scientific infrastructure relies on the seamless integration of advanced research objectives with structured engineering practices. In science-based facilities, this intersection often presents challenges, as scientific exploration encounters the rigor and discipline of established engineering workflows. This presentation examines key lessons drawn from industrial engineering environments and their application to greenfield scientific projects. Emphasis is placed on the importance of clearly defined processes, cross-disciplinary communication, and adaptability to complex, evolving requirements. By aligning engineering excellence with scientific ambition, new opportunities emerge to enhance the efficiency, scalability, and impact of next-generation research facilities.

Speaker: Hooman Shahrooz (European Spallation Source) -

14:27

HRPD-x Concept to Definition: A Summary of some of the instrument design challenges and how they've been resolved. 1m

HRPD-x is ISIS’s new high resolution powder diffractometer, replacing HRPD which was the first instrument to detect neutrons back in 1984. It will be the first neutron instrument to be delivered as part of the Endeavour Program and is due to be installed and commissioned in 2027. HRPD-x will offer significantly increased detector coverage and reduced background whilst also boosting reliability, stability and adding new sample environment capabilities.

As many of the main sub-assembly design work packages are closing and progressing to manufacture, this poster aims to highlight some of the more challenging aspects of the design and how they were resolved. It will focus on the following:

-

A new 3D printed, thin walled, radial collimator using B10 infused

filament. -

A positive pressure Argon system with 0.8mm thick aluminium windows

with large surface area -

Producing wavelength shifting fibre detectors with a precise

curvature over a large span. -

Developing an integrated blockhouse and interlock system within a new

building around a theoretical sample point.

Speaker: Tim Maundrell -

-

14:28

Replacement work with 2nd generation T0 chopper in J-PARC MLF 1m

In J-PARC MLF (Materials and Life Science Experimental Facility), we maintain and operate 6 T0 choppers on JAEA instruments. The T0 choppers had been more than 10 years since they were installed, and they had begun to deteriorate over time, and performance improvements were also necessary.

We developed 2nd generation T0 chopper which is high-speed and high-durability, and 2 of them have been already replaced at 4SEASONS (BL01) and SENJU (BL18). In 2025, We replaced high-durability T0 chopper at TAIKAN (BL15).

The 2nd one is different from a previous one in various points. The mount of the 2nd one was designed to be compatible with previous one, but an extra vibration sensor and a few sensors for the phase control system are added. For that reason, we had to put some extra cables which are about 30 meters in total, and a junction device box had to be put between T0 chopper and control panel. At each beamline, various devices and machines have been already installed besides choppers under the shielding blocks and particularly TAIKAN has 3 large vacuum chambers whose width occupies almost full width of the beamline and there is little space to put the cables. Therefore, we carefully considered the way to install the T0 chopper and the space to put the cables. Moreover, the junction device box had to be put under the shielding, where the box has a possibility to be irradiated by scattered neutrons. To prevent the box from breakdown, we covered it with B4C resin.

The previous one has only 25Hz speed, but new one can run at 25, 50, 75, and 100Hz. At this point, the biggest problem is resonance. So, we have to consider resonance frequency at each speed. Additionally, peripheral equipment also has its own resonance frequency respectively. The T0 choppers rotate a heavy hammer at high speeds and, vibration from the T0 chopper could cause large effects to the equipment. Therefore, we took measures to prevent the problems from vibration.

The poster will describe the replacement of a T0 chopper and adjustment to mitigate vibration so that the chopper can be operated normally.Speaker: Ryota Komine (J-PARC MLF) -

14:29

MArMOT - Multiplexed Array for Mapping On Thales 1mSpeakers: Lester Clarke, Paul Steffens, Pierre Courtois (Institut Laue Langevin), Stéphane Roux (ILL), emmanuel villard

-

14:31

Refurbishment of D11+ SANS Spectrometer 1mSpeaker: Stephane Fuard

-

14:32

State of the art technology for Neutorn Monochromators at the ILL 1mSpeaker: Gilles Pastrello

-

14:33

Next and MoTo 1mSpeakers: Ronan Moreau, christophe dumoulin

-

14:01

-

15:30

→

16:00

Coffee 30m

-

16:00

→

16:45

NEUTRON SOURCES

-

16:00

Target exchange system for the HBS HiCANS neutron source 15m

Within the Jülich High Brilliance Neutron Source (HBS) project Forschungszentrum Jülich is developing a novel High Current Accelerator-driven Neutron Source (HiCANS). The HBS generates neutrons using nuclear (p,n) reactions caused by a pulsed proton beam. The target has a design life of one year. Due to the high activation after one year of operation, the replacement process must be carried out remotely. As part of a one-year operating phase of an HBS technology demonstrator, an experimental target exchange system has been built and tested. Based on the experience gained with the existing change system, concepts for an improved exchange system are currently being discussed. The existing concept, lessons learned and the basic concept for a revised process will be presented.

Speaker: Johannes Baggemann (JCNS, Forschungszentrum Jülich, Germany) -

16:15

Design and development of a 3 MeV lithium target for the High Brilliance Neutron Source (HBS) 15m

Within the High Brilliance Neutron Source (HBS) project, Forschungszentrum Jülich is developing a novel High Current Accelerator-driven Neutron Source (HiCANS). The concept is scalable, ranging from low-flux university-based sources to high-flux facilities equipped with a full instrument suite for user operation. At the heart of any neutron source is the target, which determines both neutron yield and the operational limits of the system. For compact accelerator-based sources such as HiCANS, the key challenge is to achieve efficient neutron production while ensuring thermal and structural robustness under high-current proton beams.

As part of the HBS technical design report, a 70 MeV tantalum target was developed, manufactured, and successfully tested. It was then operated at the HBS target station demonstrator at the JULIC accelerator, Forschungszentrum Jülich. Following the shutdown of JULIC in 2023, the target station will be relocated to Spain to enable continued operation and further experience, using the 3 MeV accelerator at ESS Bilbao. For it's operation at the ESS Bilbao, The HBS system requires a new target that is optimized for low-energy operation while remaining compatible with the existing station geometry and it’s cooling structures.

A thin lithium target (0.2 mm) has been identified as a suitable option, provided it is supported by a robust backing plate to ensure effective heat dissipation, mitigate blistering, and extend target lifetime. In parallel, measures to protect against lithium corrosion are being developed. This presentation will outline the initial design process of the lithium target, highlighting key challenges such as heat removal of atleast 5 kW, structural integrity of the lithium layer, bonding methods with the backing plate, material compatibility, hydrogen implantation, activation properties and overall lifetime.

Speaker: Sivaraj Aditya Sambamurthy (JCNS-2, Forschungszentrum Juelich GmbH) -

16:30

The Moderator Test Station at the Spallation Neutron Source 15m