Speaker

Description

enter code here35 years ago, the Oak Ridge National Laboratory (ORNL) High Flux Isotope Reactor (HFIR) powder diffractometer began life at beam line HB-4 complete with a compliment of 32, vertically oriented, point tube, 3 He detectors arranged radially about the sample position 2.7° apart. It served there for 10 years before being shelved to make way for the Cold Guide Hall project. 17 years ago, the diffractometer was exhumed and rebuilt at the HB-2A beam line, and the detector array was increased to 44 tubes. While the flux improved dramatically, the 2.7° gaps demanded that the entire array be moved across the gaps in 0.05° steps to generate a full diffraction pattern with sufficient overlap between tube signals to reliably fit the data.

This stepping consumed vast amounts of beam time and prevented the diffractometer from performing in-situ studies. To respond to the user community and advisory committee recommendations, several concepts surfaced to meet the requirements of a 150°, gamma insensitive, fixed position detector, that reduced count times and at least maintained the resolution of the HB-2A detector. These features combined with a target budget of $500K for design, procurement, assembly, testing, and installation along with a timeline demanding the project complete before the HFIR Beryllium Reflector Replacement (HBRR) necessitated the use of up to 144 pre-existing tubes inherited from the Intense Pulsed Neutron Source

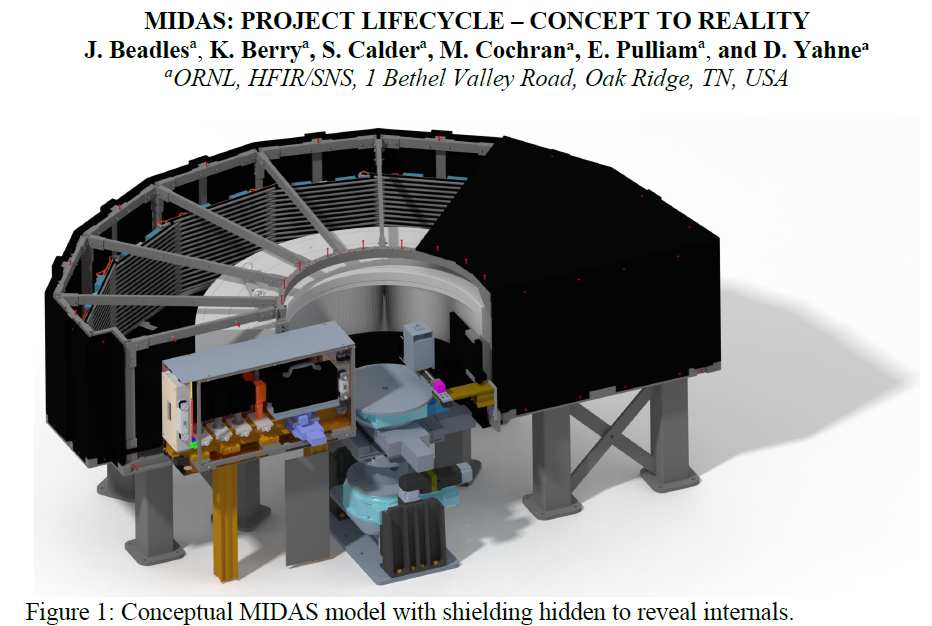

(IPNS). This resource along with further budgetary uncertainty led to the development of a novel design, the Modular Interdigitated Detector Array System (MIDAS).

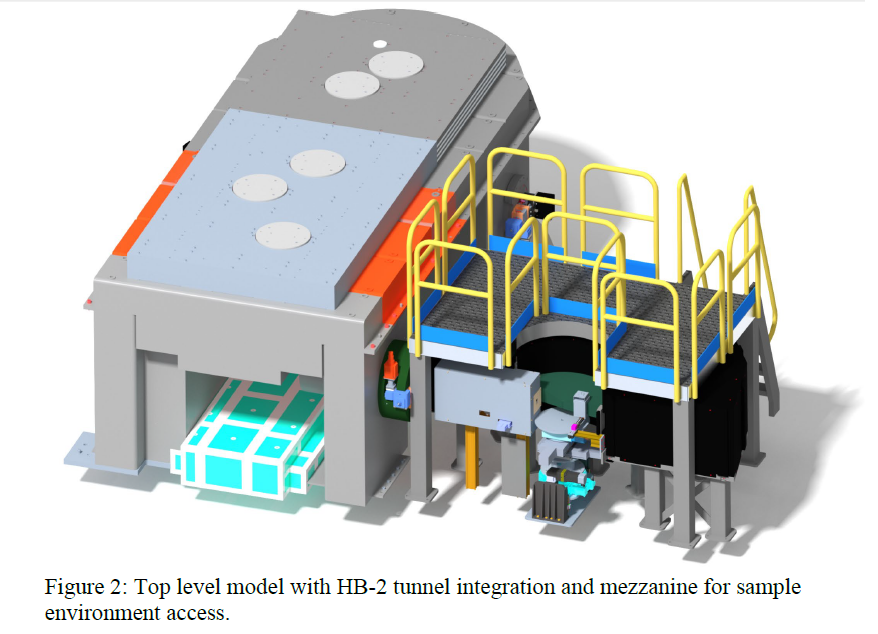

The MIDAS instrument upgrade project has been progressing successfully throughout 2025 with final design underway and advanced procurements submitted. The design requires support from the instrument science team, engineering and design, neutronics analysis, data acquisition (DAQ), technical craft and more. The Linear Position Sensitive Detectors (LPSD) will be mounted to the base and interweaved together to form a detector array with full 150° coverage. An oscillating radial collimator, currently being manufactured, will sit between the detector array and sample center. A modular shielding design and support system surrounds the internal

components and will be created using 3D printed molds to fabricate custom B 4 C epoxy casts. Finite Element Analysis (FEA) and structural analysis were used to refine the support system design and base plate requirements. Neutronics analysis optimized the shielding and developed an improved lower profile beam stop. A translation/rotation stage will also be utilized to align a pre-monochromator collimator inside the HB-2 tunnel. Detector electronics and instrument controls will be upgraded to a new EPICS platform and improve user instrument configuration options. The MIDAS upgrade is planned for installation during the Spring 2026 HFIR outage with neutron commissioning to proceed afterwards.